PSU Plastic Frame - Alkaline Water Electrolysis Components

High Strength Corrosion Resistant · Superior Electrical Insulation · Custom Solutions

Product Overview

With the rapid development of the hydrogen energy industry, alkaline water electrolysis technology holds a significant position in large-scale hydrogen production due to its low cost and mature technology. However, traditional metallic frames are prone to corrosion in strong alkaline environments, leading to metal ion dissolution and affecting equipment safety and performance stability.

echemstore supplies professional PSU (Polysulfone) plastic frames specifically designed for alkaline water electrolysis systems. Manufactured from high-performance polysulfone material, these frames offer excellent corrosion resistance, lightweight design, high mechanical strength, and superior electrical insulation properties, making them ideal for alkaline water electrolysis equipment.

Widely used in water electrolysis for hydrogen production, fuel cells, electrolytic cells, and other electrochemical equipment, providing stable and reliable frame solutions for research institutions and industrial production.

Key Features

- Excellent Corrosion Resistance: Long-term stable operation in strong alkaline environments

- High Mechanical Strength: Tensile strength 70.3 MPa, flexural strength 106 MPa

- Superior Electrical Insulation: Volume resistivity 3.0×10¹⁶ Ω·cm

- Versatile Supply Options: Sheets, flow channel frames, custom services

Product Services

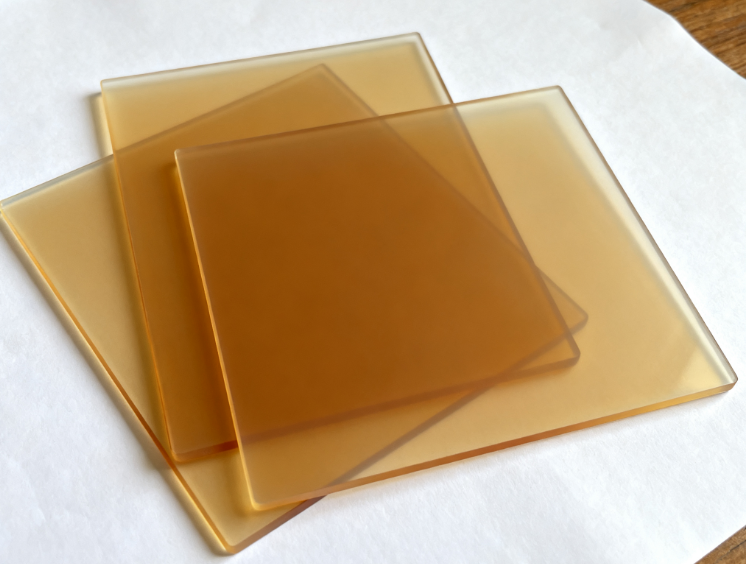

Sheet Supply

Various thickness PSU sheets available, cut to specified dimensions according to customer requirements, ensuring product quality and precision

- Multiple thickness options

- Precision cutting service

- Quality assurance system

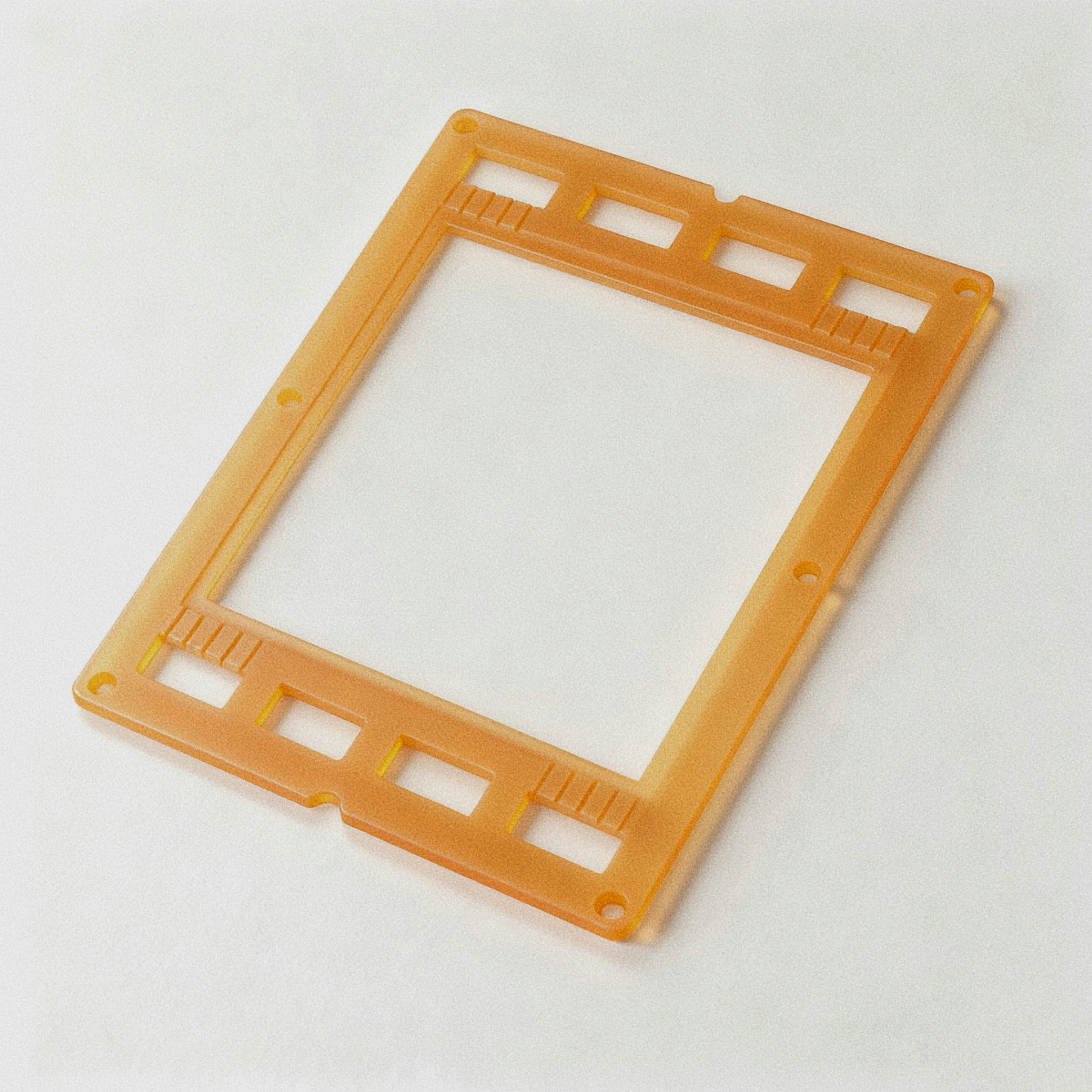

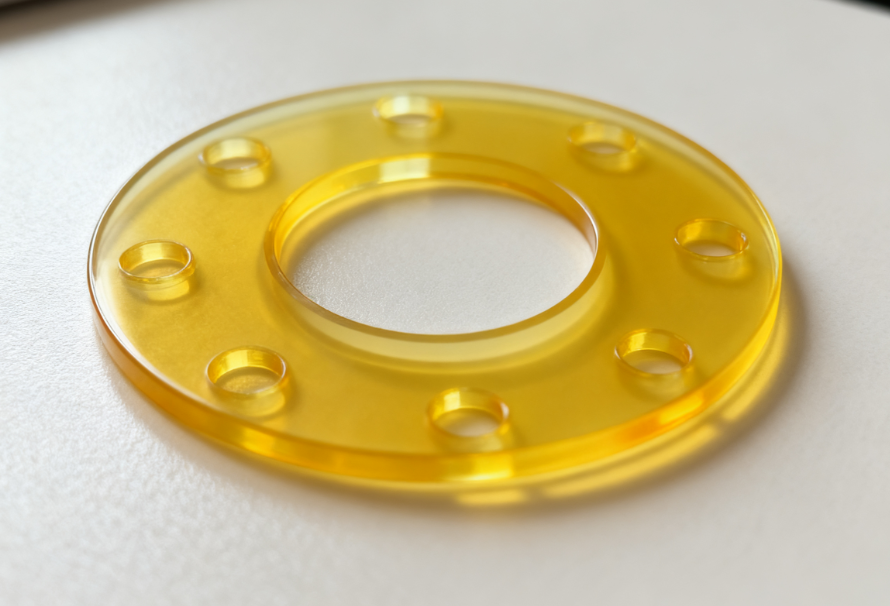

Flow Channel Frames

Pre-designed flow channel frame products ready for direct use in water electrolysis equipment assembly, improving production efficiency

- Pre-designed flow channels

- Ready-to-install

- Optimised fluid distribution

Custom Services

Personalised frame design and processing services based on specific customer application requirements

- Bespoke design solutions

- Professional engineering team

- Rapid response service

Technical Support

Professional technical consultation and application guidance to ensure optimal product performance

- Expert technical consultation

- Application guidance service

- After-sales technical support

Technical Specifications

Standard technical parameters for PSU raw material. Actual sheet parameters may be adjusted according to processing requirements

| Property | Value | Unit | Test Standard |

|---|---|---|---|

| Specific Gravity | 1.24 | g/cm³ | ASTM D792 |

| Melt Flow Rate | 6.5 | g/10 min | ASTM D1238 |

| Shrinkage Rate | 0.70 | % | ASTM D955 |

| Water Absorption (24h) | 0.30 | % | ASTM D570 |

| Property | Value | Unit | Test Standard |

|---|---|---|---|

| Tensile Modulus | 2480 | MPa | ASTM D638 |

| Tensile Strength | 70.3 | MPa | ASTM D638 |

| Elongation at Break | 50-100 | % | ASTM D638 |

| Flexural Modulus | 2690 | MPa | ASTM D790 |

| Flexural Strength | 106 | MPa | ASTM D790 |

| Izod Notched Impact Strength | 69 | J/m | ASTM D256 |

| Property | Value | Unit | Test Standard |

|---|---|---|---|

| Volume Resistivity | 3.0×10¹⁶ | Ω·cm | ASTM D257 |

| Dielectric Strength | 17 | kV/mm | ASTM D149 |

| Dielectric Constant (1 kHz) | 3.04 | - | ASTM D150 |

| Dissipation Factor (1 kHz) | 1.0×10⁻³ | - | ASTM D150 |

| Property | Value | Unit | Test Standard |

|---|---|---|---|

| Heat Deflection Temperature (1.8 MPa) | 174 | °C | ASTM D648 |

| Glass Transition Temperature | 185 | °C | DSC |

| Continuous Use Temperature | 150 | °C | UL746B |

| Flammability Rating | V-0 | - | UL94 |